26 August 2024

Adhesion problems? Get the right pre-treatment!

“Why isn’t my adhesive sticking? Why doesn’t it stick anymore? I swear I haven’t changed anything!” Customers often find themselves in these types of nagging predicaments when manufacturing rubber adhesive compounds.

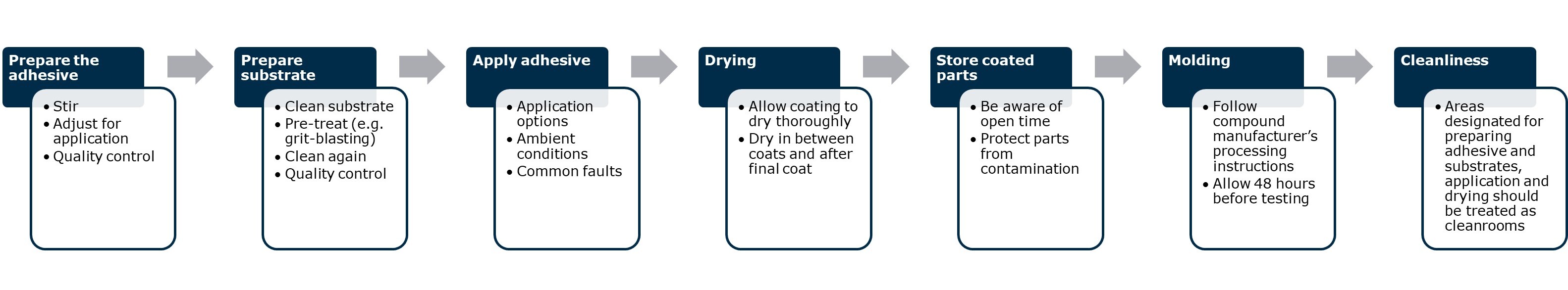

At Nordmann, and through our new partnership with H.B. Fuller, we’re able to support customers by drawing on years of experience in processing rubber compounds. We’ve found that around 90% of the adhesion problems that customers experience come down to inadequate pre-treatment, which is why we’d like to highlight seven important steps that you can take to make sure you get it right every time:

1. Prepare the adhesive

- Stir the adhesive until you have a homogeneous liquid. Keep foam levels down (stir under a mirror).

- Adjust the adhesive as appropriate for the desired application method.

- Inspect the adhesive for quality (e.g. by measuring flow time).

2. Prepare the substrate

- Use a suitable detergent to clean the substrate until it is free of oil, grease and/or dust.

- Pre-treat the surface to increase its surface/contact area for the adhesive, e.g. by blasting/grinding.

- Thoroughly clean the substrate again using an appropriate cleansing agent and ensure the surface is free of sanding/blasting dust.

- Quality-check the substrate, e.g. through visual inspection and measuring its roughness

3. Apply the adhesive

- Check application equipment and surroundings for possible contamination.

- Apply a test layer of the adhesive and measure the its dry film thickness. Make any necessary adjustments.

- Measure air temperature and humidity.

- When using a water-based adhesive, ensure substrates are heated to 50-60 °C in order to achieve optimum film formation.

4. Dry as recommended by the technical data sheet

- Dry the adhesive.

- Allow for additional drying when applying primer and cover.

5. Store parts coated with adhesives properly

- Protect parts coated with adhesive from contamination, e.g. dust, oil and mechanical stress.

- Store parts coated with adhesive at room temperature and the appropriate level of humidity.

- Be aware of the adhesive’s specific open time.

6. Vulcanize rubber components

- Proceed according to the compound manufacturer’s recommendations.

- Allow for an aging time of at least 48 hours before testing.

7. Cleanliness

- Areas in which adhesives and substrates are prepared, applied and dried must be treated as cleanrooms in order to avoid soiling/contamination by dust, oil, etc.

It’s not sticking? Let us know! We’re happy to help.

Dr. Gunther Seifert

Technical Sales and Product Manager | Synthetic Rubber & Rubber Chemicals

Nordmann, Rassmann GmbH

Dr. Fabian Verheyen

Business Manager | Synthetic Rubber & Rubber Chemicals

Nordmann, Rassmann GmbHDistributed in:

Germany.

22 September 2025

NORCOMP silicone and

fluorosilicone compounds

Nordmann offers customers in the rubber industry a wide range of synthetic rubbers as well as rubber chemicals, with ready-to-use silicone and fluorosilicone compounds rounding out the range. With over 20 years of experience as a developer and manufacturer of NORCOMP silicone and fluorosilicone rubber compounds, the multinational chemical distributor is also a recognized maker-independent compounder.

16 September 2025

Thermax® – The problem-solving Carbon Black

Thermax® is more than just a filler - it is the intelligent problem solver for modern elastomer formulations. Developed to meet today's challenges, Thermax® delivers exactly what technical buyers and material developers are looking for: performance, safety, and efficiency in one.

21 July 2025

Sustainable additives from Europe

For over five decades, Nordmann partner Condensia Química has been synonymous with pioneering innovations in the development and manufacture of esters and polyesters. As a renowned market player, the company offers sustainable additive solutions for a wide range of applications, including PVC, rubber, lubricants, polyurethanes, adhesives, coatings, personal care products, and PLA-based materials.