Nordmann: more than distribution …

Having long-standing partnerships with suppliers all over the world means that we are able to assure customers a high and consistent level of product quality that is backed up through regular audits.

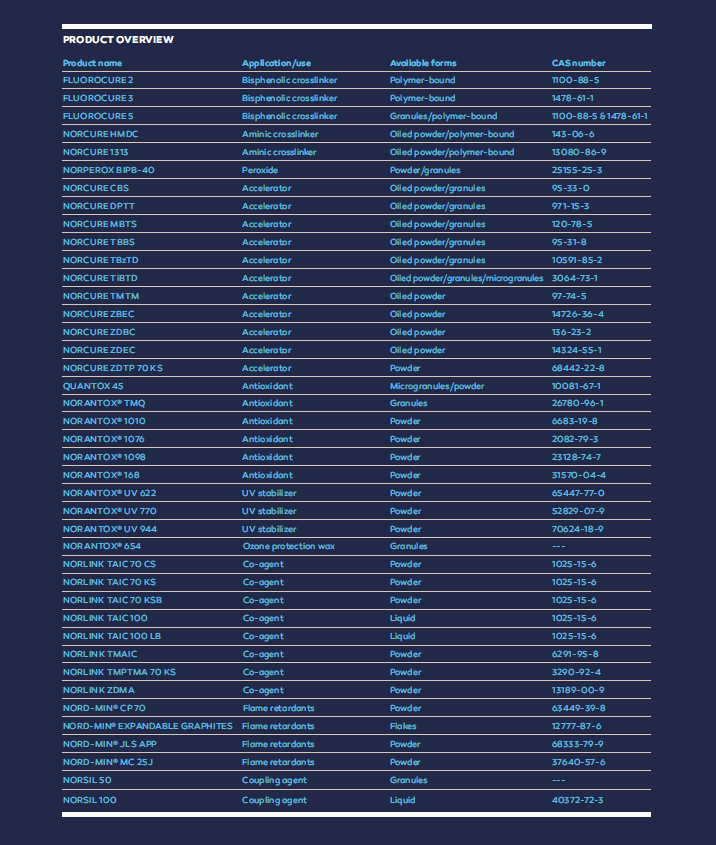

Crosslinking agents

Nordmann’s FLUOROCURE bisphenolic crosslinkers for FKM polymers are excellent for individually adjusting crosslinking properties. They are available as polymer-bound materials to ensure superior dispersibility during the mixing process. An accelerator (FLUOROCURE 2) and crosslinker (FLUOROCURE 3) can also be purchased separately and custom-dosed.

FLUOROCURE 5 is a pre-reacted blend of FLUOROCURE 2 and 3 in a ratio of just under 4:1. We also carry a polymer-bound grade of FLUOROCURE 5 that features 50% active content.

As a crosslinking agent for acrylic rubbers (AEM, ACM), we offer NORCURE HMDC in pure powder form as well as a phlegmatized, oil-bound version (NORCURE HMDC-I) and a polymer-bound grade (NORCUR HMDC-70). Compared to the pure powder, both NORCURE HMDC-I and NORCURE HMDC-70 can be better dispersed in compounds.

As an alternative to HMDC, Nordmann supplies NORCURE 1313-50 N. The aromatic structure of the active ingredient – BAPP – lowers reaction speed more than HMDC and thereby increases scorch safety levels. We recommend this crosslinking agent for applications that need to have continuously high service temperatures.

NORPEROX BIPB-40 rounds out our portfolio as a crosslinking agent for peroxides. We supply it as either a powder or in pressed granule form with an active content of 40% on blended calcium carbonate/silica. We recommend using it with our coagents in order to minimize the chance of undesirable side reactions. In this way, the amount of peroxide used can also be reduced.

Coagents/crosslinking activators

Coagents or crosslinking activators are usually unsaturated organic compounds that react with radicals formed during peroxide crosslinking. This increases crosslinking density and speed. Nordmann offers a variety of different coagents/activators in the NORLINK product line.

TAIC is supplied in liquid form as either NORLINK TAIC 100 or NORLINK TAIC 100LB, depending on the level of purity required. For better handling, Nordmann also carries TAIC as a dry liquid on two different mineral substrates: silica (NORLINK TAIC 70 KS & NORLINK TAIC 70 KSB) or calcium silicate (NORLINK TAIC 70 CS).

As a peroxide crosslinking agent for FKM in particular, we offer NORLINK TMAIC. Compared to TAIC, using NORLINK TMAIC increases resistance to fuels and biodiesel. It also achieves lower values of CR than TAIC does. This makes it a great choice for extruded products.

Also for extrusion, we have a TMPTMA (also called TRIM) available as a dry liquid on silica (NORLINK TMPTMA 70 KS).

Our NORLINK ZDMA improves not only crosslinking density but also rubber-to-metal adhesion in both peroxide- and sulfur-crosslinking compounds.

Accelerators

Nordmann offers a wide range of accelerators under the brand name NORCURE, including a range of nitrosamine-free products. These are available either as pure powders, oil-coated powders or granules, depending on the product type:

- Dithiocarbamate: NORCURE ZBEC, NORCURE ZDBC, NORCURE ZDEC

- Phosphate: NORCURE ZDTP 70 KS

- Sulfenamide: NORCURE CBS, NORCURE TBBS

- Thiazole: NORCURE MBTS

- Thiurame: NORCURE TiBTD, NORCURE TBzTD, NORCURE DPTT (also used as sulfur donor), NORCURE TMTM

Antioxidants

Nordmann has a range of its own antioxidants, both primary and secondary. Primary antioxidants – usually aromatic amines and hindered phenols – scavenge and destroy radicals before they can react with polymers. Typically, the radicals are then converted into inert by-products such as alcohols or water.

NORANTOX® TMQ is an aromatic amine, while our Quantox 45 is a diphenylamine. This antioxidant causes light discoloration but is often used as a heat stabilizer in NBR, EPDM and CR applications, as well as others. For hindered phenols, customers can choose from the following: NORANTOX® 1010, NORANTOX® 1076 and/or NORANTOX® 1098.

Secondary antioxidants (also called preventive antioxidants) convert chain-initiating hydroperoxides to nonradical products. Our NORANTOX® 168 is a phospite that falls under this category.

UV stabilizers or light stabilizers, including HALS (hindered amine light stabilizers) are also part of our portfolio: NORANTOX® UV 622, NORANTOX® UV 770 and NORANTOX® UV 944.

Anti-ozone waxes like our NORANTOX® 654 are often used to protect components that are subject to static stress. At room temperature, this blend of paraffin and microcrystalline waxes is not readily soluble in the rubber matrix – meaning that processing temperatures should be kept above the product’s melting point in order to increase solubility. Depending on the subsequent service temperature of the resulting vulcanizate (as well as the chain length of the wax and the polymer used), the wax will migrate to the surface of the final material and form a closed, protective film.

Flame retardants

For over a decade, Nordmann has been supplying NORD-MIN® CP 70 – a chlorinated paraffin that is often used as a flame retardant in chlorinated polymers such as CR, CSM or CPE. This material has already been used successfully for many years in the production of conveyor belts – proof of the consistently high quality of NORD-MIN® CP 70.

In addition, one of NORD-MIN® CP 70’s most compelling features is its very low content of short and medium-length chlorinated paraffin. With ongoing discussions concerning the ban on short-chain chlorinated paraffins (SCCP) and medium-chain chlorinated paraffins (MCCP), this means that the product can be used without issue.

Nordmann also offers a broad-ranging portfolio of halogen-free flame retardants that includes, for example, NORD-MIN® expandable graphites – each with different starting temperatures and expansion volumes. Additionally, the Nordmann portfolio features NORD-MIN® ammonium polyphosphates: the core component for intumescent systems. To round out the line, we supply a melamine cyuarnurate marketed under the name NORD-MIN® MC.

Bonding agents

Silanes serve as coupling agents for bonding silica fillers and rubber. Our liquid version, NORSIL 100, is a bifunctional organosilane (TESPT) that provides superior bonding effects, which in turn has a positive impact on e.g. abrasion and wear resistance. Typical applications for this product include tires, rollers, hoses, shoe soles, etc. To ensure that silanol is formed during the mixing process, however, temperatures of at least 130 °C must be reached.

NORSIL 50 is a half-strength (50%) preparation supplied on a kerosene wax carrier, which reduces the reactivity of the silane with atmospheric moisture. This improves storage stability significantly.

Further information

For detailed product information please contact our experts: sales(at)nordmann.global

Distributed in: Worldwide