Capa® LT 3 for low-temperature polyurethanes

For applications in which plastics need to remain flexible across a wide range of temperatures, polyurethane (PU) is the material of choice. Selecting unsuitable materials could mean that finished plastics crack when bent, ultimately resulting in component failure.

Since even the best PUs can become brittle as temperatures plunge, it is critical to choose the correct grade to maintain safe and reliable performance. This is especially true for applications in oil and gas, aerospace, and the automotive industry that utilize equipment such as seals, gaskets and other flexible parts made from PU.

Pushing the boundaries of low-temperature performance

Using its own proprietary technology, Ingevity created the Capa® LT 3 polyol to enable the formulation of PUs with enhanced low-temperature performance that fulfill the rigorous demands of modern industrial applications.

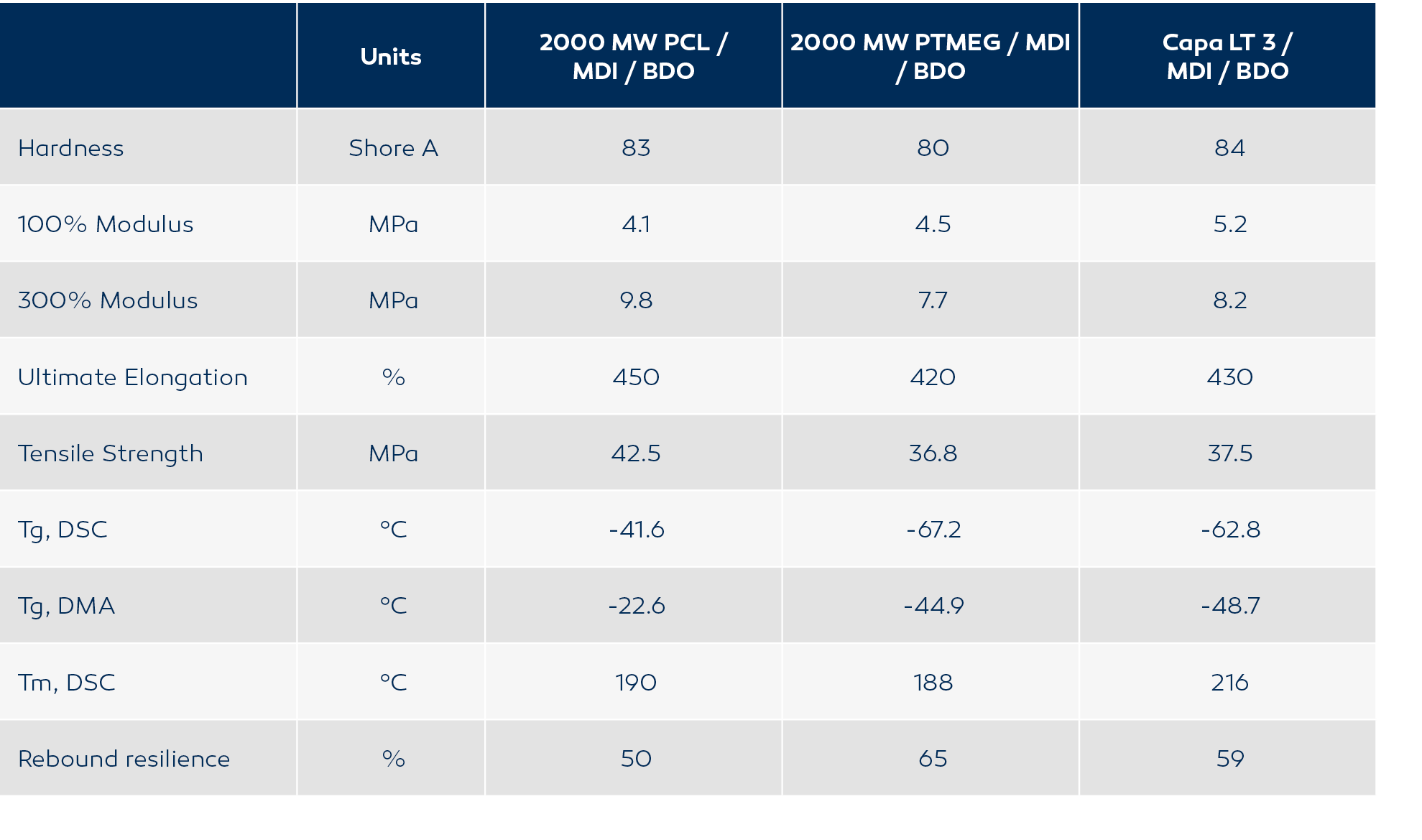

In addition to a low glass transition temperature (Tg), using Capa® LT 3 also improves viscoelastic properties at low temperatures.

This new technology from Ingevity makes it possible to produce polyurethanes that can be used in temperatures up to 20 °C lower than those based on conventional polyols, all without compromising their other mechanical properties.

In addition to flexible industrial components, Capa® LT 3 is also ideal for producing PUs used in specialist footwear such as ski boots and inline skates.

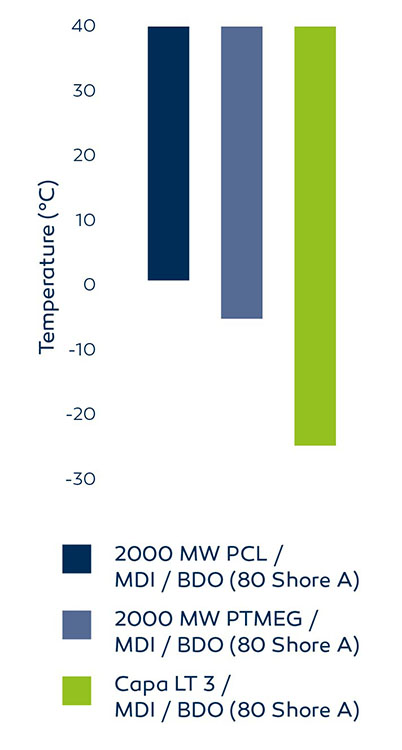

Typical minimum operating temperature for PU articles (80 Shore A formulation, based on polyol/MDI/BDO), in which viscoelastic properties remain consistent.

DMA analysis showing the viscoelastic properties of 80 Shore A PU formulations at low temperature extremes. PUs based on Capa® LT 3 demonstrate consistent performance down to significantly lower temperatures than competitors.

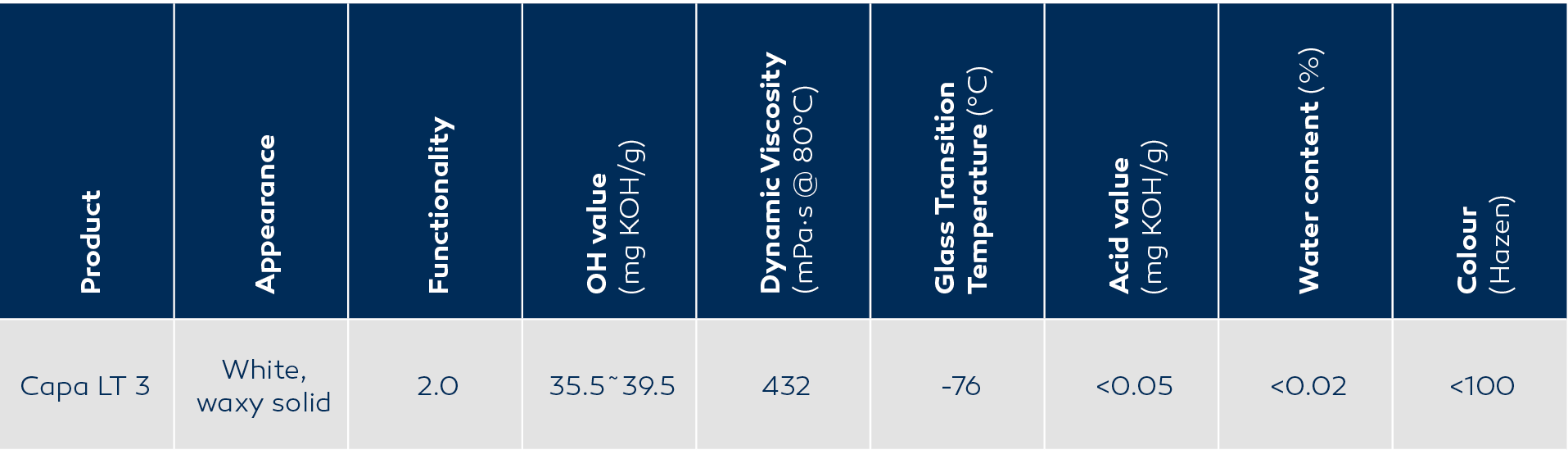

Capa® LT 3 product offerings

Comparison of physical properties of polyurethanes based on Capa® LT 3 with standard polyols

For more information, please contact:

EU SVHC regulations: Challenges and solutions for light stabilizers

Low-emission catalysts