5 June 2024

Erapol 1K Blocked Series

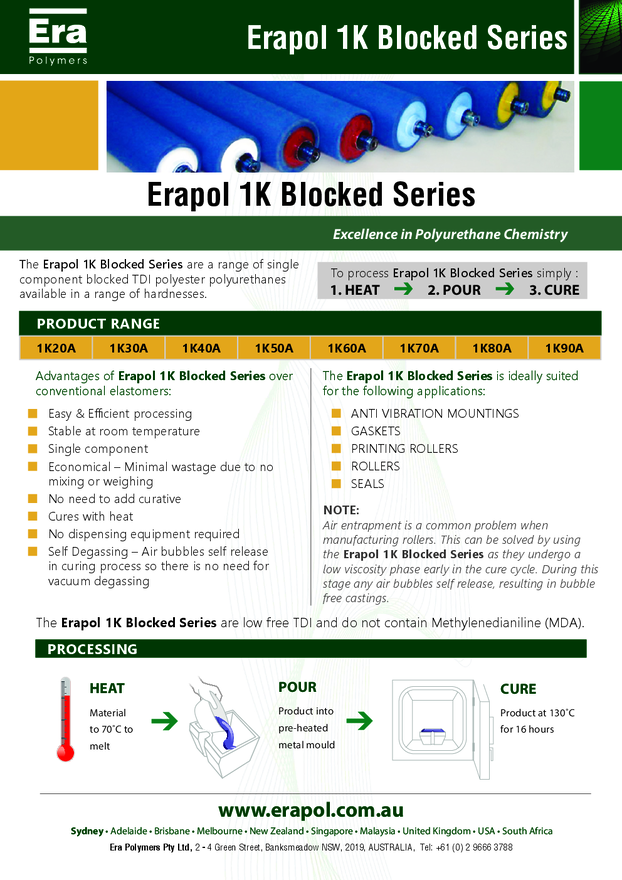

Erapol 1K Blocked Series are polyester-based, one component blocked elastomers that cure with heat. The range currently consist of products from 20 Shore A to 90 Shore A. The 1K series are stable at room temperature. As one component products there is no secondary mixing with an added component required to set the product. The blocked systems contain no free isocyanate, no MOCA (MbOCA) or any solvents.

Product range

| 1K20A | 1K30A | 1K40A | 1K50A | 1K60A | 1K70A | 1K80A | 1K90A |

Processing

Advantages of single-component technology:

- Easy and efficient processing

- Stable at room temperature

- Economical processing with minimal waste

- Isocyanate is chemically bonded

- Self degassing through the pre-heat process

- No machine technology required for dosing

- Small batch production possible thanks to small containers with 20 kg filling quantity

Typical applications:

- Seals

- Pressure rollers

- Technical rollers

Typical Physical Properties – Erapol 1K

| Typical Physical Properties | 1K20A | 1K30A | 1K40A | 1K50A | 1K55A | 1K60A | 1K80A | 1K90A |

|---|---|---|---|---|---|---|---|---|

| Processing Temperature (°C) | 55 – 75 | 55 – 75 | 55 – 75 | 55 – 75 | 55 – 75 | 55 – 75 | 55 – 75 | 55 – 75 |

| Mould Temperature (°C) | 120-130 | 120-130 | 120-130 | 120-130 | 120-130 | 120-130 | 120-130 | 120-130 |

| Post Cure at 135-140° (hrs) | 16 – 18 | 16 – 18 | 16 – 18 | 16 – 18 | 16 – 18 | 16 – 18 | 16 – 18 | 16 – 18 |

| Hardness (Shore A) | 16 – 25 | 30 – 36 | 35 – 41 | 47 – 53 | 52 – 58 | 61 – 67 | 75 – 85 | 87 – 93 |

| Resilience (%) | 23 | 34 | 29 | 33 | 32 | 29 | 40 | 32 |

| Tensile Strength (MPa) | 2.6 | 2.0 | 7.6 | 6.5 | 10 | 14 | 18 | 13.9 |

| Elongation (%) | 540 | 435 | 605 | 600 | 790 | 725 | 575 | 500 |

| Angle Tear Strength (kN/m) | 13.9 | 7.8 | 12.6 | 18.3 | 21.2 | 32 | 53 | 55 |

| Trouser Tear Strenhth (kN/m) | 2 | <0.5 | 1 | 5.5 | 5.4 | 12 | 16 | 16.2 |

| Cured Density | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

Distributed in:

Austria, Benelux, Germany, Finland, Italy, Sweden and Switzerland.

For more information, please contact:

Ole Gerlach

Senior Technical Sales & Product Manager | Polyurethane Elastomers

Nordmann, Rassmann GmbH

10 June 2024

CO2NVERGE®: innovative CO2-based polycarbonate polyols

Innovative CO2-containing CO2NVERGE® polyols produced by Nordmann partner Aether Industries - as long term exclusive toll producer and nowadays license holder from Aramco - are high-performance polyols. They provide the unique combination of improved performance AND sustainability.

5 June 2024

Erapol 1K Blocked Series

Erapol 1K Blocked Series are polyester-based, one component blocked elastomers that cure with heat. The range currently consist of products from 20 Shore A to 90 Shore A. The 1K series are stable at room temperature. As one component products there is no secondary mixing with an added component required to set the product. The blocked systems contain no free isocyanate, no MOCA (MbOCA) or any solvents.

18 March 2024

Nordmann partnering with new Albemarle subsidiary Ketjen

Earlier this year, Albemarle’s Catalyst and Performance Chemicals Solutions division transitioned from being a company department to a wholly-owned subsidiary known as Ketjen. Ketjen is now entirely dedicated to the development and manufacture of curatives, organometallics and catalyst solutions.