NECOWELTM 790 – A new waterborne polyester polyol for 2K PU-coatings

Products that are successful in the market and preferred by end-users should have a high content of renewable raw materials, a low content of residual harmful monomers but the same protective effect as common coatings available.

ASK Chemicals has succeeded in developing a new polyester polyol emulsion named NECOWELTM 790 that meets all requirements.

NECOWELTM 790 is the ideal candidate for the formulation of high-quality 2K PU coatings that offers a biobased content of approx. 20wt% and the successful removal of harmful monomers by maintaining all final product characteristics that are well known from ASK Chemicals` NECOWELTM product family.

Table 1: Specifications and key characteristics of NECOWELTM 790.

| NECOWELTM 790 | |

|---|---|

| Solid content / wt% | 38-41 |

| Viscosity@25°C / mPas | 1500-3000 |

| pH-value | 7.0-8.0 |

OH-content / wt% OH-number / mg KOH g-1 | 5-6 170-195 |

| Biobased content / % | 18-20 |

| Cross cut test / CDC-panel | Gt0 |

| Blistering limit / µm | 100 |

Table 2: Starting formulation for a clear-coat based on NECOWELTM 790.

| Clear coat | Component | Weight % |

|---|---|---|

| A | Binder | 89.00 |

| B | Surfactant A | 0.45 |

| C | Thickener | 0.60 |

| D | Water | 8.72 |

| E | Surfactant B | 0.09 |

| F | Defoamer | 0.14 |

| G | Easy-to-clean | 1.00 |

The clear coat formulation based on NECOWELTM 790 as presented in table 2 was mixed with a HDI-hardener/butyl glycol acetate premix in a ratio 3:1, adjusted to a spray viscosity of 30-35s and finally applied on CDC-panels for further evaluation. A comfortable open-time allowed film-thicknesses of 100 µm and more by spray-application in one step.

Hardness of the cured film was analyzed by pendulum damping procedure (6°-3°) and showed values around 140s after 7 days as a result of the high cross-linking density. This finding can be attributed to the high OH-value that also provides excellent chemical resistance towards solvents and alkaline solutions. The gloss level at 20° was above 80 GU and confirms a high gloss coating that can be adjusted with matting agents if needed.

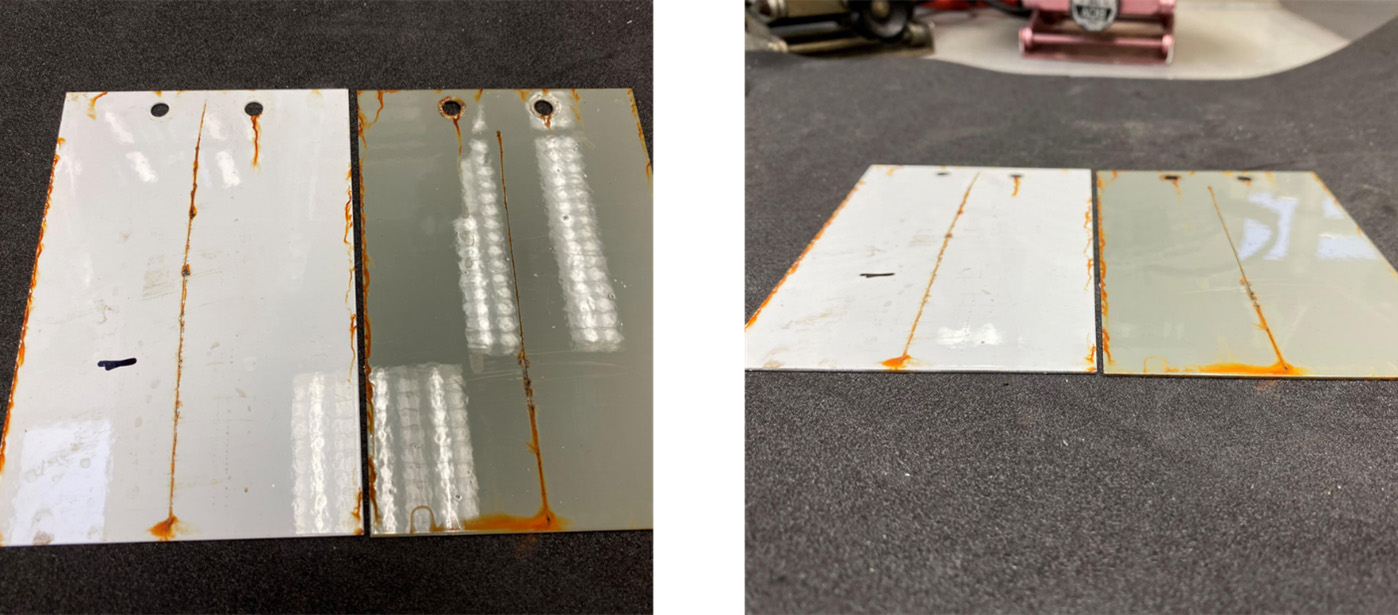

Salt-spray test conditions according to DIN EN ISO 9227 after 20 days and subsequent cross-cut-test analysis indicate excellent intercoat adhesion without delamination.

Picture 1: Salt spray test of NECOWELTM 790/isocyanate-coated CDC-panels after 20 days.

Thus, NECOWELTM 790 represents a new generation of label-free polyester polyol emulsions that are curable with hydrophilized isocyanate hardeners containing remarkable contents of renewable raw materials by maintaining all other features like high gloss, good hardness development and chemical resistance.

For more information please contact:

Nordmann at the European Coatings Show 2025: A look back

Driving Innovation: Nordmann's Application Labs and Technical Centre