NORRHEO Organoclays for solvent-based and solvent-free systems

The rheological effectiveness is achieved through the formation of hydrogen bonds between the edges of the individual clay platelets, which creates the house-of-cards structure and ultimately leads to the gelation of the coating. Under shear forces, the coating system becomes more fluid, allowing for optimal processing. After application, the viscosity gradually rebuilds thanks to the thixotropic flow behavior, resulting in a viscosity increase with good leveling.

The incorporation of NORRHEO organoclays into coating systems can be done either by direct addition to the mill base (SED - grades) or as a pregel (S- grades) under high shear forces.

The preparation of the pregel is particularly used for the activation of NORRHEO CLAY S4 and S8 using an activator (polar solvents) under high shear forces. This allows the individual clay platelets to delaminate and swell.

Common activators include:

- methanol/water (95:5)

- ethanol/water (95:5)

- acetone/water (95:5)

- propylene carbonate/water (95:5)

- wetting and dispersing agents

- propylene carbonate for UV systems or systems where the addition of water is undesirable

The 5% water content helps polar solvents form hydrogen bonds.

Our NORRHEO CLAY SED-1, SED-2, and SED-7 generally do not need to be activated before use in coating systems. Since they are already pre-activated, they can be added directly to the mill base. In aromatic-free, aliphatic solvents, the addition of 10–20% activator can sometimes be beneficial even for pre-activated types.

NORRHEO organoclays must be fully wetted with solvent or a binder/solvent blend before activation.

Other wetting and dispersing agents should only be added to the system after the NORRHEO orgaoclays have been fully activated. Otherwise, the performance of orgaoclays may be reduced or eliminated.

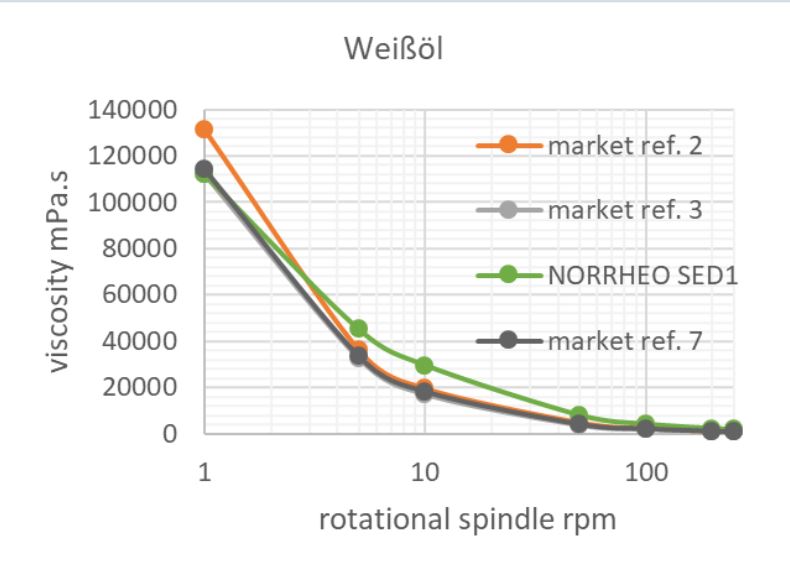

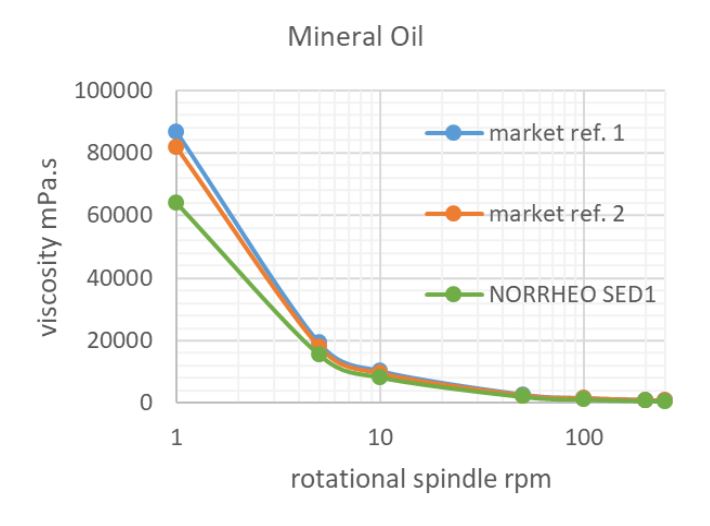

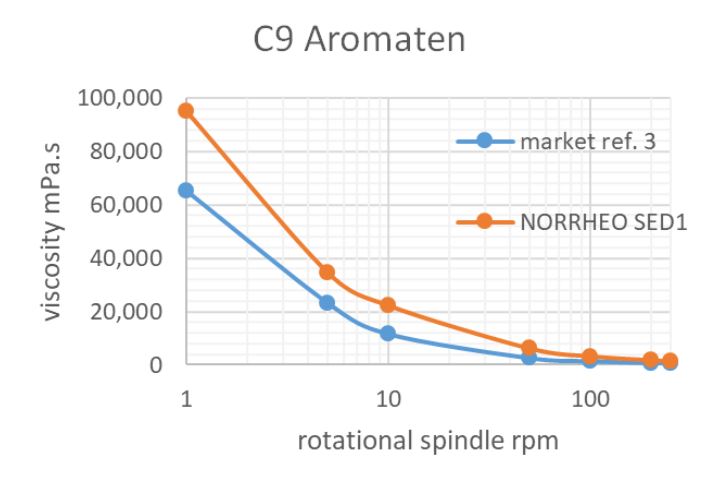

Measurements of the gel strength of NORRHEO CLAY SED-1 in various solvents (see the graphics below) show similar properties to common products on the market and demonstrate good thickening efficiency in a variety of solvents typically used in the coatings industry.

It should be emphasized that Nordmann conducted the laboratory tests in its Technical Centre in UK in pure solvents and not in solvent blends, as they typically occur in a coating formulation.

The NORRHEO product portfolio includes different grades depending on the polarity of the coating systems.

For more information, please contact:

Distributed in:

Worldwide.

Nordmann at the European Coatings Show 2025: A look back

Driving Innovation: Nordmann's Application Labs and Technical Centre